Pipejacking is a trenchless technique for installing underground pipelines, ducts and culverts. Powerful hydraulic rams are used to push specially designed pipes through the ground behind the TBM while the TBM itself is excavating through the ground. The method provides a steerable, flexible, structural, watertight pipeline behind the TBM. The technique allows large diameter pipes to be installed accurately without disturbing the ground above, such as railway, motorway, road & river crossings. For smaller diameters we can offer a range of Microtunnelling, Auger Boring and Guided Auger trenchless techniques.

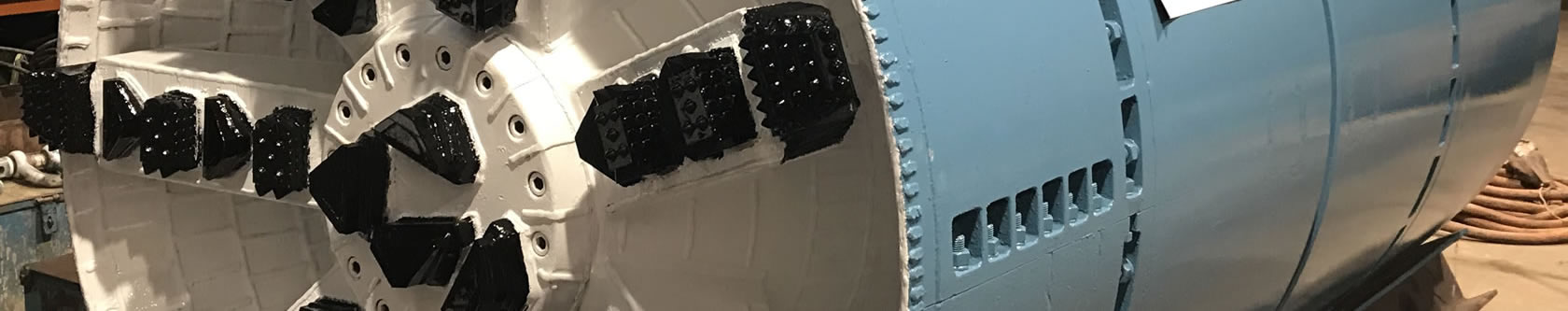

Akkerman TBMs

Akkerman Tunnel Boring Machines have been widely used worldwide since the early 1960s. B&W purchased their first hydraulic Akkerman TBM in the year 2000 and have expanded their fleet since.

Today B&W own Akkerman TBMs to suit pipes of 1500, 1800 & 2100 diameter. Intermediate sizes can be accommodated using skin-up kits.

All our TBMs can be fitted with one of several types of head to suit different ground conditions.

Muck Head – used in clay, silt, sand & gravel

Carbide head – used in weak to medium strength rock

Closed head – used for boring unstable soils; hydraulic doors prevent ground loss whilst excavating the face

Earth Pressure Balance [EPB] TBMs

B&W’s fleet also includes two EPB machines manufactured by Tunnel Engineering Services

These electrically driven 1500 & 1800 EPBs can be used in wet and unstable ground, where foams at the cutting head are used to treat the ground and the rate of excavation is controlled by the capacity of the screw auger system.

Both EPB machines can be fitted with rock heads and used in open face mode to cut rock with strengths up to 250Mpa

B&W also have a fleet of remote operated microtunnelling equipment as an alternative technique for a range of diameters.