Auger Boring

B&W can offer both guided and unguided auger [Auger Boring] techniques for trenchless installation of pipes.

Auger Boring [sometimes referred to as Thrust Boring] is an unguided horizontal earth boring technique typically used to install a sleeve or product pipe on a set line and grade from a drive/launch pit to a reception pit. Launch pits can be battered or supported excavations or even segmental shafts.

Suitable for the trenchless installation of ducts, water and gas mains where exact line and level aren’t critical. They provide a cost effective and quick way of crossing other services, roads and highways, and are often used on cross country pipeline schemes.

The auger head excavates the ground and the spoil is conveyed via a continuous flight auger screw back to the thrust pit. Casings & auger screws are added and driven behind the preceding sections until the reception pit is reached.

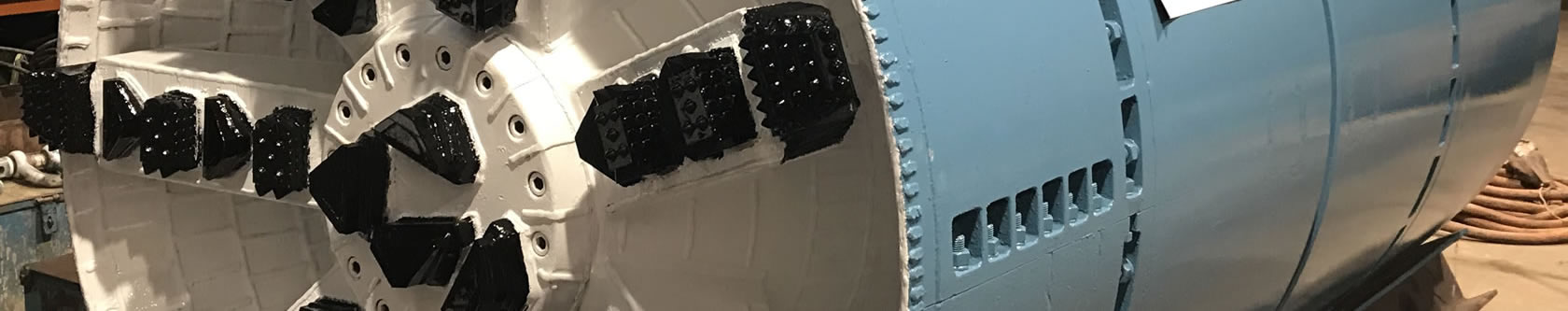

B&W own several machines to suit pipe sizes from 300mm to 1500mm diameters. The equipment can be fitted with our various heads from Robbins and Tunnel Engineering to suit the prevailing ground conditions:

Muck Head – used in clays, silt, sand and gravel

Carbide Head – used in weak to medium strength rock

Rock Boring

B&W also have Rock Boring equipment consisting of Small Boring Units [SBUs] and Robbins motorised units [MSBUs].

The SBUs are non-steerable heads utilise the thrust and torque of the auger bore machine, suitable for hard rock up to 250Mpa. These SBUs have cutting heads suitable for 600, 900, 1050 & 1200mm pipe diameters.

The MSBUs are steerable and can be operated manually or remotely from a surface mounted kiosk. These are available for 1200 & 1500mm diameters.

For installation of larger diameters B&W can also offer Microtunnelling and Pipejacking.